The GY series workbenches are designed to support heavier loads and come equipped with six hydraulic cylinders for stable lifting. The hydraulic lifting deviation is within 2%, ensuring precision and accuracy. The workbenches feature fixing and clamping devices that allow for efficient cutting on the front workbench while loading takes place on the rear one. This design ensures cutting precision and loading accuracy. Additionally, the QH.SPAC intelligent cutting system includes fast intelligent perforation mode, fast intelligent knife collection mode, and process database customization for ease of use. The hydraulic system used is of high quality, and the distance between the upper and lower worktables can reach 120mm. The individual worktables can be adjusted to vary in distance. Furthermore, all worktables can be exchanged to the back end, making machine tool maintenance easier.

A laser metal cutter is a tool that utilizes a laser beam to cut through metal. This process is known as laser cutting. Laser cutting is a non-contact cutting process, which means that the laser beam does not directly touch the material being cut.

The laser beam is generated by a laser resonator, which is directed through a series of mirrors to a focusing lens. The focusing lens concentrates the laser beam into a small spot, which can be as small as a few thousandths of an inch in diameter. This focused laser beam is then directed onto the material being cut, which is melted, burned, or vaporized by the intense heat of the laser.

Laser metal cutters are used in a wide range of industries, including automotive, aerospace, and manufacturing. They are ideal for cutting intricate shapes and patterns, as well as for making precision cuts. They can cut through a variety of metals, including steel, aluminum, and brass.

One of the advantages of laser cutting is its precision. Laser metal cutters can produce cuts with tolerances as small as a few thousandths of an inch, which makes them ideal for applications that require high precision. Additionally, laser cutting is a fast and efficient process, which means that it can be used to produce large quantities of parts quickly and accurately.

In conclusion, laser metal cutters are powerful tools that offer a wide range of benefits. They provide high precision cutting, fast and efficient operation, and the ability to cut through a variety of metals. As such, they are an important tool in many industries and for a wide range of applications.

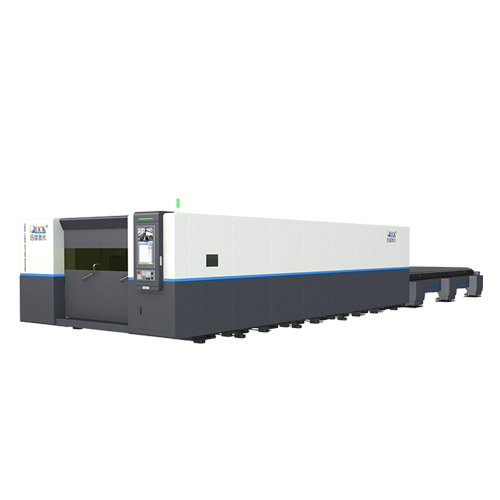

Our automatic pipe laser cutting machine is designed to provide users with exceptional ease-of-use, allowing for simple adjustments and seamless application when cutting a wide variety of pipe sizes and shapes. With an advanced automatic adjustment chuck, our machine is the perfect choice for any cutting needs you may have.

With our 3D and 2D laser cutting machines, we can handle any application, regardless of lot size, sheet size, or thickness.

Our design and engineering teams have worked with customers from every industry to design, manufacture, and deliver marking solutions built for specific applications.

Metals to polymers, thick to thin, large to small, lasers can do it all. we can offer you comprehensive advice for all production possibilities.

Customer Service Products Privacy Imprint Company

2023 Air Tronics