Laser cutting machines are an essential component of modern construction machinery, including concrete slabs, cranes, pavement machines, loaders, port machinery, excavators, fire-fighting machinery, and sanitation machinery. With high-power plate laser cutters, three-dimensional laser cutting machines, and pipe laser cutters, businesses can enjoy comprehensive solutions that significantly increase production efficiency.

APPLICATION ENGINEERING

Successful laser solutions

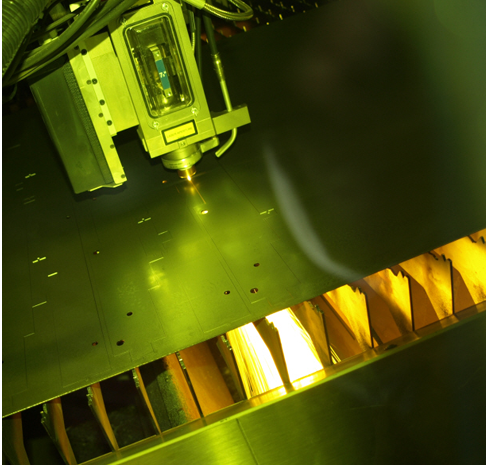

High power laser cutting

In the manufacturing processes of construction machinery, a large number of round, square, and special-shaped holes need to be cut on plates of various thicknesses. This task requires a high level of precision and accuracy. Thanks to laser cutting and blanking technology, production efficiency has significantly improved. This has led to better product quality and faster manufacturing speed for construction machinery.

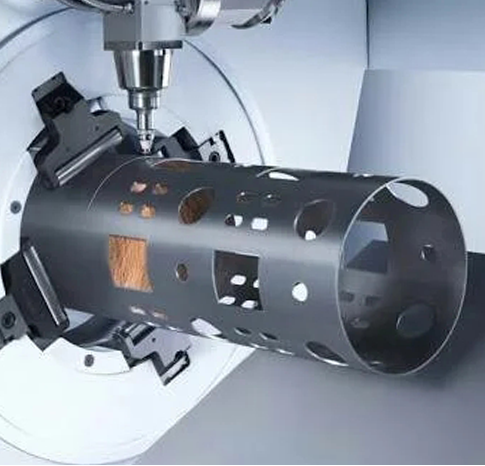

High efficiency laser tube cutting

During the production and manufacturing stages of construction machinery, various pipes are required such as square pipes, round pipes, and T-shaped steel tubes. Our high-efficiency laser tube cutting with fiber laser pipe cutting function ensures that all actions and functions associated with pipe cutting, including feeding, length measurement, cutting, and blanking, are fully automated, reducing processing time and manpower requirements.

Agricultural machinery laser cutting

At Air-tronics, we possess extensive experience in laser cutting. Our cutting machine features remarkable cutting ability and "flying" cutting speed, while maintaining ultra-high stability and delivering high-quality processing at an extremely low operating cost. In addition, we offer professional and customized technical services and solutions to numerous customers in the agricultural machinery manufacturing industry, with an equipment sales volume that leads the industry.

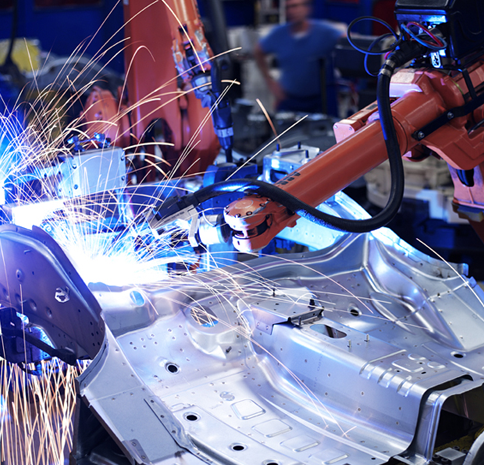

Laser welding of agricultural machinery

Air-tronics laser welding machines offer numerous advantages that make them highly desirable. These include a high depth-to-width ratio, a small weld width, a small heat-affected zone size, a low deformation rate, fast welding speed, and pore-free welds. They also allow for accurate control with small light spots, precise positioning accuracy, and easy automation, making them a popular choice for various agricultural machinery production and processing processes. It's no surprise that these machines are widely utilized by agricultural machinery producers.

Our products stand for:

We provide excellent cut edge and surface quality to ensure superior performance. Our focus on automation, process expertise, and smart systems engineering maximizes productivity. We use premium parts to ensure efficient material use and optimum service life. Our robust product design, combined with reliable process monitoring, guarantees stable processes.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com