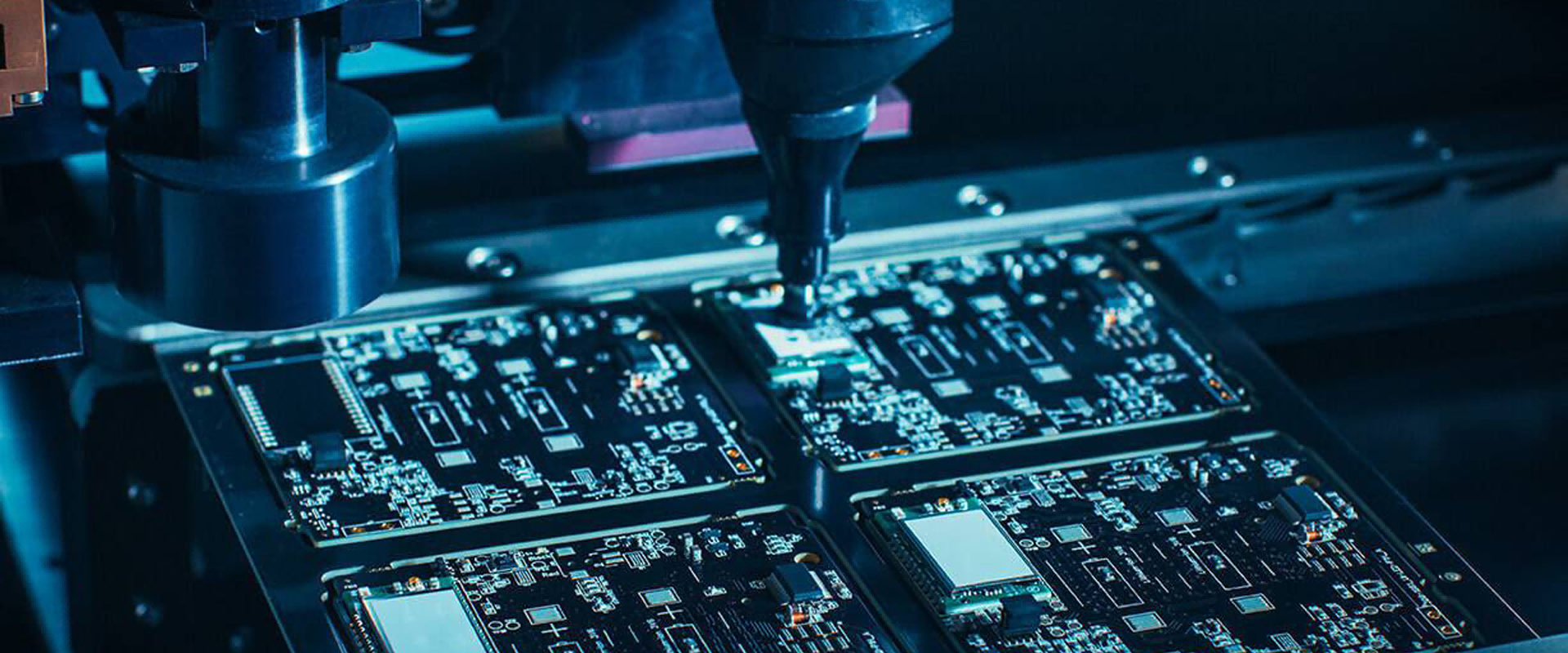

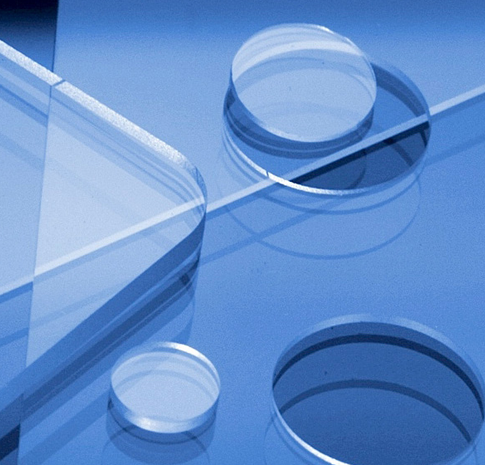

Progress in microelectronics is inextricably linked to laser technology. With laser sources and systems, metals and plastics can be quickly and precisely cut, welded, marked, and ablated, providing swift yet accurate solutions for cutting, welding, and marking, as well as ablation solutions that meet rigorous quality standards. Laser welding and cutting technology is also ideal for supporting automated production systems, ensuring that optimal quality standards are achieved with confidence.

APPLICATION ENGINEERING

Successful laser solutions

Air-tronics fiber lasers and automated systems have earned a reputation in the consumer electronics industry for their exceptional reliability, flexibility, efficiency, high power output, beam quality, compactness, and cost-effectiveness. When it comes to laser technology, consumer electronics applications require precise pulse repetition rates for maximum productivity and precision. This is where fiber lasers excel, thanks to their outstanding beam quality, flexibility, and stability, which make them ideal for micromachining applications. Recently, Air-tronics has expanded our product line from infrared wavelengths to include green and ultraviolet wavelengths, with the development of picosecond and high femtosecond pulse capabilities. With these advancements, our fiber laser technology can benefit an even wider range of consumer electronics applications.

Customer Benefit

With laser technology, customers can enjoy numerous benefits:

1. Laser technology eliminates tool wear, reducing operating and material costs.

2. Fast speed working greatly improves production efficiency.

3. Permanent markers promote product anti-counterfeiting ability.

4. The laser marking machine is a high-tech, environmentally-friendly product that won't produce any chemical substances harmful to human body and environment.

5. Laser technology doesn't require ink or chemical solvents, resulting in a clean and non-polluting working environment.

6. Laser technology can create classier products with additional value, ultimately increasing brand awareness.

7. The traceability system allows for effective control over all aspects of the whole manufacturing process and the operating costs.

8. The good flexibility of laser marking machine increases the diversity of products, making it a highly versatile tool for businesses.

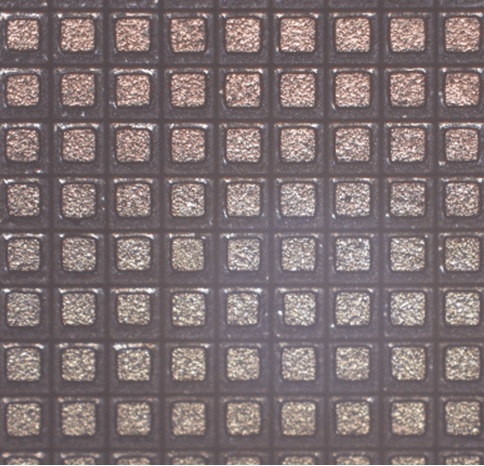

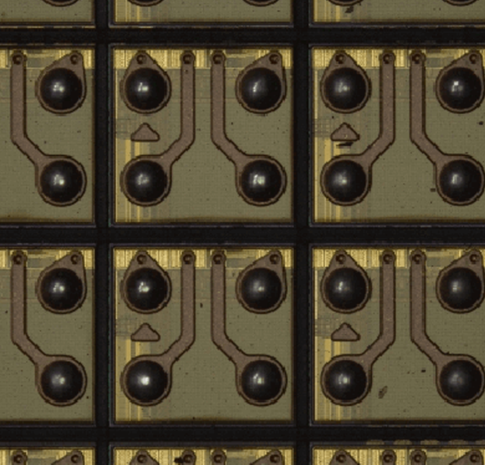

Cold precision processing of chips, packages, and printed circuit boards

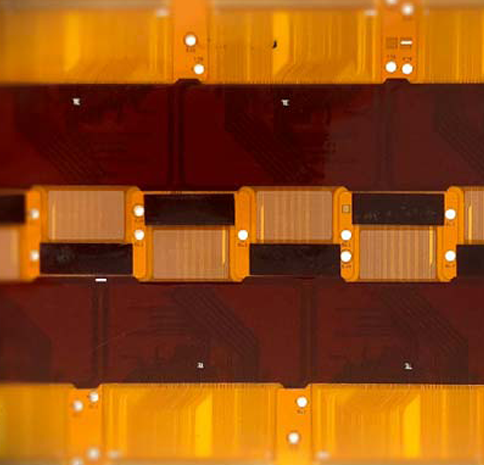

Once circuits have been assembled on silicon wafers and exposed, the next challenge in the electronic process chain is separating them into individual chips. To ensure minimal kerfs, high edge quality, and minimal thermal impacts to sensitive chips, ultrashort pulse lasers from AeeFar Airtronics Tech are utilized for separation. With its laser processing system, materials can be handled with precision and without heat influences. These lasers are also ideal for trimming sensitive modules (system-in-package), processing multi-material printed circuit boards, and drilling microvias in silicon and glass. Additionally, AeeFar Airtronics Tech lasers are often used for targeted layer ablation, cutting films, and marking.

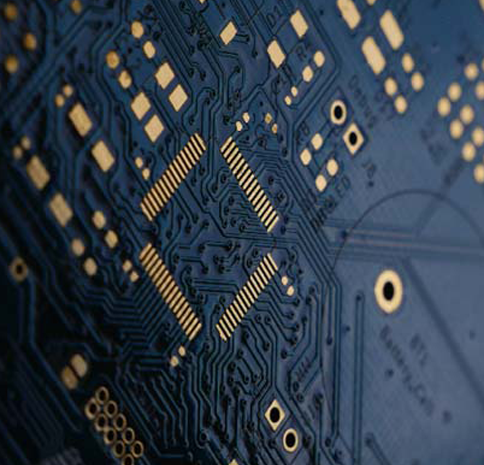

Electronic Circuit

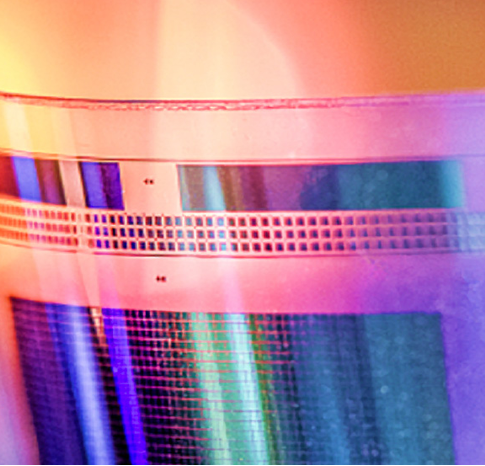

The PCB industry is a crucial component of electronic information. Thanks to the rapid advancements in 3C electronics, smart cars, IC carrier boards, and other markets, its growth has been significantly spurred on - leading to new demands for its processing technology. Precision laser technology is becoming increasingly popular due to its non-contact, lossless processing capabilities, and as a result, more PCB factories are implementing it. Air-tronics offers innovative cutting, marking, and automation solutions that are tailored specifically to meet the unique needs of this sector.

Semi-conductor industry

Air-tronics is a prominent player in the semiconductor industry, delivering cutting-edge solutions and industry-specific machines that cover various post-process steps for wafer processing, including laser annealing, debonding, cutting, marking, and other laser application technologies that cater to the different needs of enterprises. Our advanced laser precision machining for wafer/chip manufacturing significantly enhances production efficiency while improving accuracy by an order of magnitude. With our lasers, we produce large quantities of reproducible, high-quality products that are ideal for electronics industries.

Applications

The applications of laser welding are extensive and include: mobile phones, digital cameras, MP3 players, batteries, solid-state lighting, capacitors, relays, and cabinets.

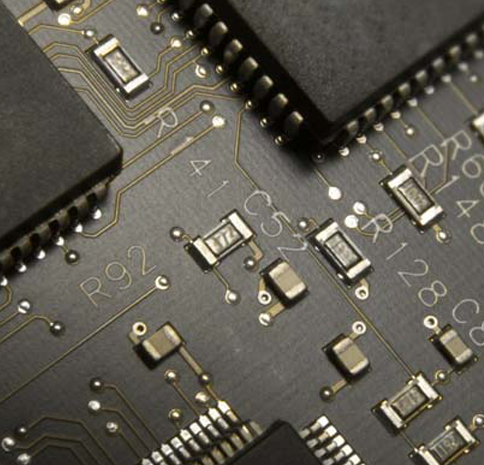

Our laser marking and engraving capabilities are vast and diverse. We can mark and engrave a wide range of products including keyboards, cell phones, computer mouse, computer monitors, TV remote controls, tablets, MP3 players, chromecast components, A/C control units, circuit breakers, printed circuit boards, shavers, hair dryers, power supplies, printer cartridges, key fobs, hearing aids, bar codes, and 2D data matrix codes. Trust us to deliver high-quality and precise laser marking and engraving services for your products.

These are just some of the applications of laser cutting: circuit boards, capacitors, resistors, motor laminations, computer hardware, appliances, enclosures, cabinets, cell phones, and tablets. Laser cutting is a versatile technology that is used in a wide range of industries and has proven to be an effective and precise method for cutting a variety of materials.

+86 18151106863

+86 18151106863 info@airtronicstech.com

info@airtronicstech.com